AGV forklift is an unmanned forklift. It is an intelligent industrial unmanned vehicle. It does not need to be driven manually. It carries out handling operations by automatic navigation and realizes intelligent warehousing and logistics. As an important automatic handling equipment, AGV forklift has a pivotal position in the field of automation and is widely used in various fields. It is mainly applied to internal logistics automation and flexible manufacturing to realize complex handling management. Compared with the traditional manual forklift, the intelligent warehouse logistics built by AGV forklift has the advantages of efficient operation, high intensity work, high flexibility, safety and stability, and multi-scenario applications (such as areas that are not suitable for human operation such as harsh environment).

How to realize intelligent warehousing logistics with AGV forklift

With the development of social intelligence, the market demand for AGV forklifts is increasing, and the development of unmanned intelligent forklifts also boosts intelligent warehousing logistics. So how can unmanned forklifts help enterprises realize intelligent warehousing logistics? Today's unmanned forklift manufacturer - Future Robot will briefly introduce some common problems to you.

What is AGV forklift

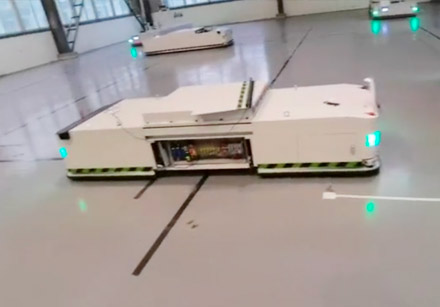

AGV forklifts sound not intuitive enough, but in fact, the popular point is unmanned forklifts. Now, most of the market uses laser navigation and positioning technology to realize automatic movement. It is an intelligent handling robot, which is mainly used to realize automatic handling of heavy goods or repeated handling, thus reducing labor costs, time costs, and improving work efficiency. Easily solve the problems of heavy handling intensity and many safety hazards in traditional warehousing logistics.

Main technology of AGV forklift

We take the unmanned forklift manufacturer-Ryeper as an example. The AGV forklift manufactured and developed by Ryeper mainly applies four technologies, involving positioning, perception, control and scheduling. They are high-precision robust navigation technology, intelligent visual perception technology, high-precision servo control technology, large-scale multi-level scheduling technology. The Rieper AGV forklift integrates its own developed "3D laser+vision" navigation perception technology, multi-axis real-time motion planning and high-precision servo control technology, which can quickly connect the on-site business process without changing the existing operation scene and meet the unmanned handling of multiple scenes. At the same time, the central control scheduling system (i.e. robot control system RCS) developed by robots in the future can realize multiple vehicle scheduling, flexible path planning, automatic obstacle avoidance, task command management, data analysis and other functions.

Advantages of AGV forklift

With the advent of intelligence, AI and big data technologies have been developed and applied. The central control scheduling system of future robots can simultaneously schedule hundreds of AGV forklift robots in the cloud based on incremental, global planning and local conflict re-planning methods, which has the advantages of high efficiency, high flexibility, security and stability. In the future, the robot AGV forklift will adapt to the site environment through sensing technology, automatically generate the semantic map of the environment, automatically plan a reasonable path, and help enterprises quickly build and upgrade intelligent storage logistics to achieve cost reduction and efficiency increase.

AGV forklift realizes intelligent warehousing and logistics

It is the trend of the times for AGV forklift to help enterprises build intelligent warehousing logistics. It can not only save labor costs, improve operation efficiency, and adapt to a variety of harsh environments. The future robot AGV forklift has landed 200+intelligent warehousing and logistics projects, with customers in more than 30 countries and regions around the world, helping customers improve efficiency by more than 30% on average, reducing N-1 manual operations on average, without changing the site, changing the existing business process, realizing 7-day deployment, 30-day online, rapid access, realizing the matching of information flow and logistics, and providing systematic support for customers' scientific, intelligent and unmanned management.